Cryo Compressed Hydrogen Tank

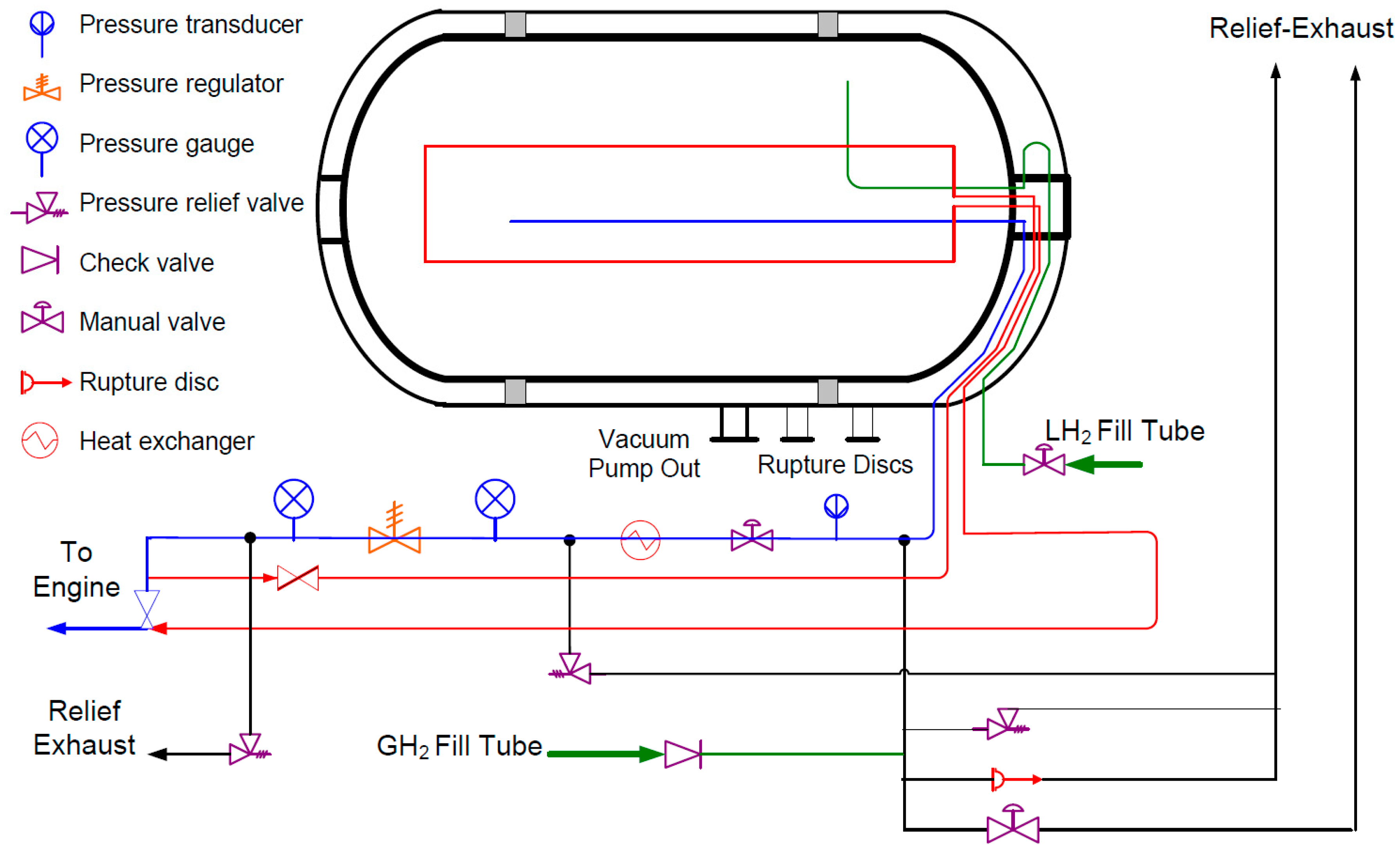

The cryo tank will contain between 6 2 kg and 10 7 kg of hydrogen if the tank is refueled with subcritical liquid hydrogen and the initial tank liner and carbon fiber temperature is between 180 k and 300 k.

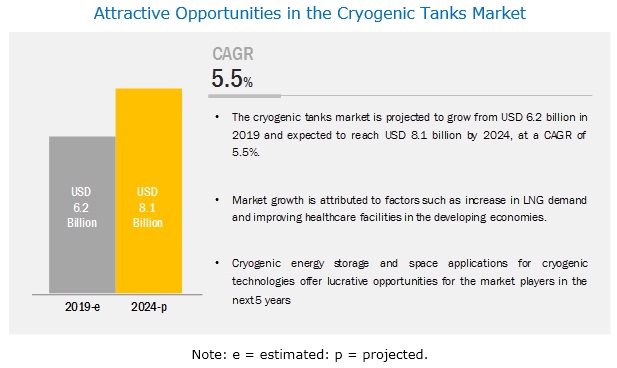

Cryo compressed hydrogen tank. At 300 k adiabatic refueling assuming that liner cf and gas are isothermal during refueling maximum possible capacity tank refueled to 272 atm 4000 psi peak pressure 4 atm initial pressure variable initial temperature additional storage capacity with pre cooled h. However the main difference is that when the hydrogen would warm up due to heat transfer with the environment boil off the tank is allowed to go to pressures much higher up to 350 bars versus a couple of bars for liquid storage. Our storage and transport facilities range from specially insulated tanks for lh 2 to pressure tight containers cylinders cylinder bundles tanks and pipes for cgh 2 at various operating sites. Like liquid storage cryo compressed uses cold hydrogen 20 3 k and slightly above in order to reach a high energy density.

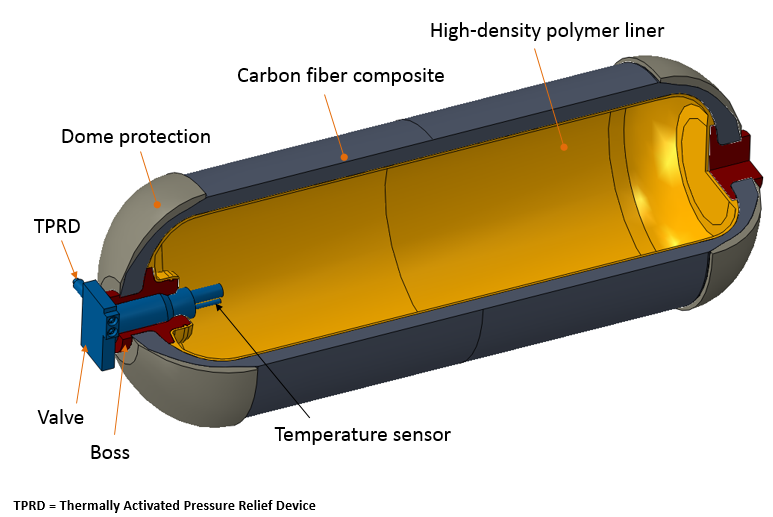

2006 2010 storing liquid hydrogen in insulated pressure vessels overcomes many of the shortcomings of compressed gas ch 2 or liquid h 2 tanks and may even open new possibilities. Refueling with compressed h. Hydrogen tank 60bar 850l. The compressed hydrogen is stored in a tank composed of a polymer liner and a composite structure that supports the mechanical forces.

Filament winding is a technique that aims to optimally strengthen the liner with long fiber composites to allow the casing to withstand high pressure. We also specialise in both compressed gaseous hydrogen cgh 2 and cryogenic liquid hydrogen lh 2 which has a temperature of 253 c. Cryo compressed hydrogen storage limits choice of materials improve resins engineered fibers and composites for cryogenic performance lack of material properties data and investigate material properties throughout understanding of failure mechanisms at 253 c to 120 c cryogenic temperatures lack of applicable codes and standards for develop acceptance testing criteria for base materials acceptance materials and engineered systems. As pointed out by aceves et al.